My sidecar engine does not have the sump plug. Some engines never had the holes drilled and tapped for the sump plug. I know most people never pull the sump plugs out for fear of damaging the threads. But I do. Or would if I could.

When your engine does wet sump it can make it much harder to kick it over. On a stroker burning Methanol it just makes it nearly impossible. With a solo I could lay it on it's side and pull the primary cover. Try that one with a sidecar.

So, after having my engine wet sump one more time I vowed to do something about it.

And here's what I did.

I installed another oil seal inside the pump. In the pump tower to be precise. The pump already has an oil seal in the body of the pump. This seal stops oil from leaking past the shaft on the scavenge side and into the feed side gears.

What HD didn't do was use an oil seal above the feed gears to stop oil leaking past the shaft into the pump tower.

So the shaft itself just runs against the cast iron pump tower. Well, until it wears enough clearance for itself to not interfere with the oils passage.

Once that happens the pump will leak. With the bike leaned on it's kick stand the oil leaks into the sump and then overflows into the primary case via the oil transfer valve in the left case half.

This really is a design flaw and should have never been allowed to persist.

Anyway, the solution is to install a seal in the pump tower

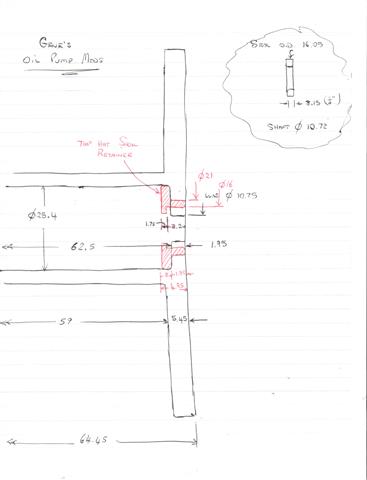

The biggest problem here is the area that should hold the seal is only about 3mm thick. And the answer to that problem is to machine up a “top hat” to be pressed into the pump tower to hold the seal.

The seal I used is the same seal used in the pump body. 26227-58 About $4 worth.

I know longer have a mill or a lathe. (Too old and blind) so I farmed out the machining operation to a local shop. Took them ½ hour to make two top hats and machine the towers and press in the top hats. They made two tools for me while they were at it.

The first is a backing tool that stops the pump tower face from distorting (bending inwards) when the top hat is pressed into place. The second is a seal installer. It can be dome without the seal installer but it's a very simple thing for anyone with a lathe to make. Both tools are.

After the top hat is pressed into place the pump tower face is faced off. HD's work here is less than stellar in any case.

So, $55 for the machine work and $8 for two seals. One pump tower is going in the race engine and one is for my big bore stroker engine.

$29.50 each.

I lose that much in oil when the thing wet sumps.

Sorry the drawing for the top hat is more a sketch than a CAD drawing but I'm a blind man. And I'm old. I might get time to do a better one later on but the critical dimensions are there.

Oh sorry we work in the metric system here. You might need to convert to inches.

I should have had a picture of the top hat as well but missed my opportunity on that one. Sorry

Here's the machines tower with the hat already pressed in. It should be clear to your machinist what is required from this. The actual line between the pump itself and the top hat is hard to see but it is there.

Here's the dimensions for the top hat.

Before the seal is installed

Or, if this is "Old Hat" and you guys don't want to know about it - let me know.

PS I am currently testing this mod on my race engine so soon enough I'll know how good it is.

__________________

"I know only too well the evil that I propose. But my inclinations get the better of me."